Converter magnesia carbon bricks refer to magnesia-carbon refractory products made of magnesia graphite as main raw materials for converter lining. The main raw materials are fused magnesia high-purity sintered magnesia high-purity graphite. Generally, it is required that MgO in magnesia is greater than equal to 95%, the content of C in graphite is greater than equal to 94%. Use phenolic resin asphalt as binder, appropriate additives according to the conditions of use, make finished products after batching, kneading, molding, heat treatment.

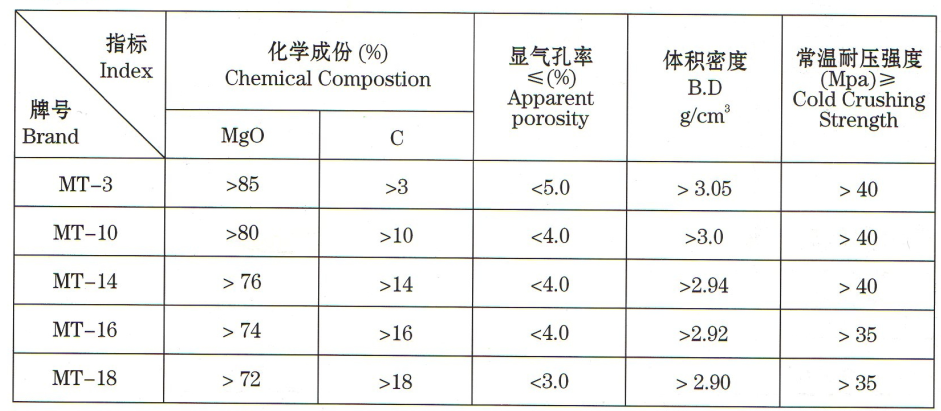

During the smelting process, the use conditions damage of each part of the converter are different. In order to achieve balanced corrosion loss, the grades quality of the selected magnesia carbon bricks are also different for each part of the converter under different operating conditions.

The temperature of the furnace mouth the furnace cap changes drastically, the slag corrosion is serious. The magnesia carbon bricks with good thermal shock resistance strong slag resistance should be selected. Except for damage caused by blowing on both sides of the trunnion, there is no protective slag layer cover on the surface, which is easy to repair, the carbon in the brick is easy to oxidize. High-quality magnesia-carbon bricks with excellent slag resistance good oxidation resistance should be built. The slag line is in long-term contact with molten slag is severely corroded by slag. It is necessary to build magnesia carbon bricks with excellent slag resistance. The splashing effect of slag molten steel when oxygen is blown on the charging side is likely to cause chemical attack, abrasion, erosion, direct impact erosion of the loaded scrap steel molten iron on the charging side. Magnesia carbon bricks with strong slag resistance, high high temperature strength good thermal shock resistance should be selected. Compared with other parts, the hearth bottom have lighter erosion. Ordinary magnesia-carbon bricks can be used. When top-bottom composite blowing technology is used, especially bottom blowing CO2, O2 other gases, the damage is more serious. High-grade magnesia carbon bricks with good oxidation resistance, thermal shock resistance, high temperature strength, strong slag resistance should be selected. Depending on the use of different parts of the converter, the selection of magnesia-carbon bricks with corresponding performance is an effective way to improve the technical economic indicators of the converter

Address: Guantun Town, Dashiqiao City, Liaoning Province

Tel: +86-0417-5365999 5365888

Sales Department: +86-0417-5365188

Finance department:+86- 0417-5365288

Technology Department: +86-0417-5365588

Fax: +86-0417-5365239 +86-0417-5365999