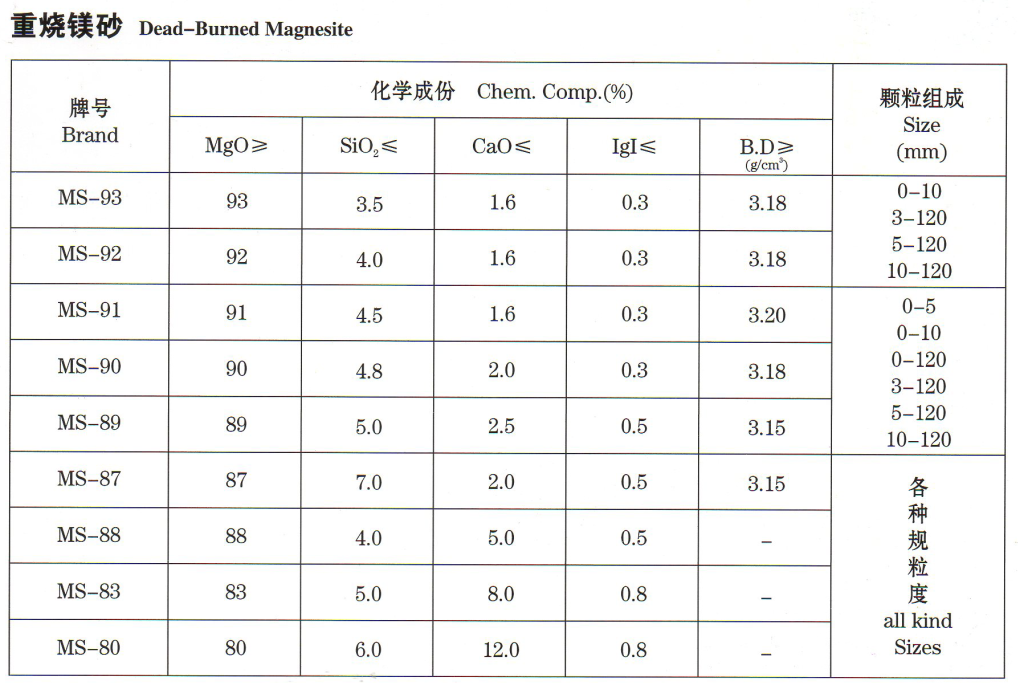

Magnesia is also called sintered magnesia. It is calcined at high temperature magnesite, brucite magnesium hydroxide obtained by the reaction of seawater with lime milk, with strong hydration ability. Mid-grade magnesia is mainly used to make basic refractory materials, such as magnesia bricks magnesia alumina bricks, those with many impurities are used to pave steel furnace bottoms.

Magnesia can be divided into two categories: natural magnesia seawater magnesia synthetic magnesia. Natural magnesia is mainly derived natural magnesite, but due to the quality of raw ore, it is difficult to obtain high-purity high-quality products. So far, seawater magnesia has become the main source of magnesia used in industrialized countries. The theoretical content of MgO in magnesite is 47.3%, the remaining impurities include CaO, SiO2, iron, etc. Magnesite is heated to 700℃~800℃ in the air to decompose, which is called "light burned magnesium oxide", further heating Above 1530℃, it becomes inactive periclase becomes hard burned magnesia, which is called "dead burnt magnesia". The synthetic seawater magnesia used in industrial production is made seawater digested dolomite. The precipitated Mg(OH)2 is calcined to obtain MgO. The calcium-silicon ratio of the synthetic magnesia used for non-fired bricks is 0.3-0.5, the calcium-silicon ratio of high-purity seawater magnesia is above 1.7, its high temperature strength.

Address: Guantun Town, Dashiqiao City, Liaoning Province

Tel: +86-0417-5365999 5365888

Sales Department: +86-0417-5365188

Finance department:+86- 0417-5365288

Technology Department: +86-0417-5365588

Fax: +86-0417-5365239 +86-0417-5365999